MBBR process includes combination of extended aeration and Floating Biological Reactor or suspended and attached growth technology. Juntai MBBR Biomedia Volume Calculator.

Calculation Of Mbbr Moving Bed Bio Reactor Sewage Wastewater Treatment Plant Calculation Youtube

After grit removal in grit chamber the wastewater containing mainly floating and settleable materials found in waste water is settled in the primary settling tank PST.

. Denitrification Anoxic tank BOD removal Aeration tank Nitrification for nitrogen removal tank---- -in Moving Bed Bio Reactor MBBR I need inputs for the following 1. MBBR PROCESS DESCRIPTION. It is very simple and easy to get a result and it can make you design easy.

Where F is the number of degrees of freedom C is the number of components and P is the number of phases in thermodynamic equilibrium with each other. Overview of MBBR Process Design Calculations. Media Retention Screen Design.

Background description of MBBR moving bed biofilm reactor wastewater treatment process as an attached growth process using plastic carriers on which the biofilm grows. 1 Size of OS Tank 565 x 285 x 125 m. Slot size should be 70 of the smallest dimension of the biofilm carrier Wedge wire.

Then you must setting your package units. The MBBR processes are used in municipal sewage treatment for. What is the methodology to design a moving bed biofilm.

Mbbr Design Calculation Biological Wastewater Treatment Processes II MBBR Processes. Blue block is the design datameter be filled in. Moving Bed Biofilm Reactor Biological Fixed Film Process Floating Free- Moving Biomass Carrier Media Media Retained in AeratedMixed Reactor 6.

Calculation of MBBR Moving bed bioreactor Sewage Wastewater treatment plant calculation. Different material properties and shapes require differing amounts of energy. Design Cost amp Benefit Analysis of a Membrane Bioreactor.

This Excel spreadsheet can be used to calculate the required MBBR tank volume and dimensions based on user input media information and wastewater design flow and characteristics. The gd in the SALR units refers to the gd of the parameter being removed and the m2 in the SALR units refers to the surface area of the carrier. If you need the mbbr media now or in the future Then please contact.

Design oxygen transfer efficiency for bod removal reactor design calculation including required total tank by another user to offer spreadsheets for mbbr process design calculations pdf. Min Design Average Flow Peak Hourly Flow Tank LW ratio 3. Anammox with MBBR Christensson et al 2013 Biofilm Media Liquid Nitritation NH 4 NO 2 AOB Anammox N 2 O 2 Aerobic Anoxic MBBR 05-15 mgL AOB in biofilm NO 2-limitation IFAS SET AS Biofilm Media Liquid Nitritation NH 4 NO 2 AOB Anammox N 2 O 2 Anoxic 05 mgL Flocs 1-3 gL AOB in flocs less NO 2-limitation.

MBBR Media Calculation. The organic load will be more or less equal to the product of the flow rate and the difference between the influent and effluent concentration. Units gm2d m2m3 1.

As you know the MBBR system needs a pre-treatment which generally includes physical treatment such as. Example MBBR Wastewater Treatment Design Spreadsheet. The key empirical design parameter used to determine the required MBBR tank size is the surface area loading rate SALR in gm2d.

MBBR Media Standard loading rates - gramm²day. How is MBBR media volume calculated. Executive Summary The design outlined in this report is tailored to address the two overriding challenges for wastewater treatment at small wineries.

Assuming a depth of125 m and LB Ratio as 2. MBBR is a type of Activated Sludge process. Process design with MBBR is based on the concept that treatment is achieved with several reactors in series and that each individual reactor is designated for a specific treatment function within the greater treatment scheme.

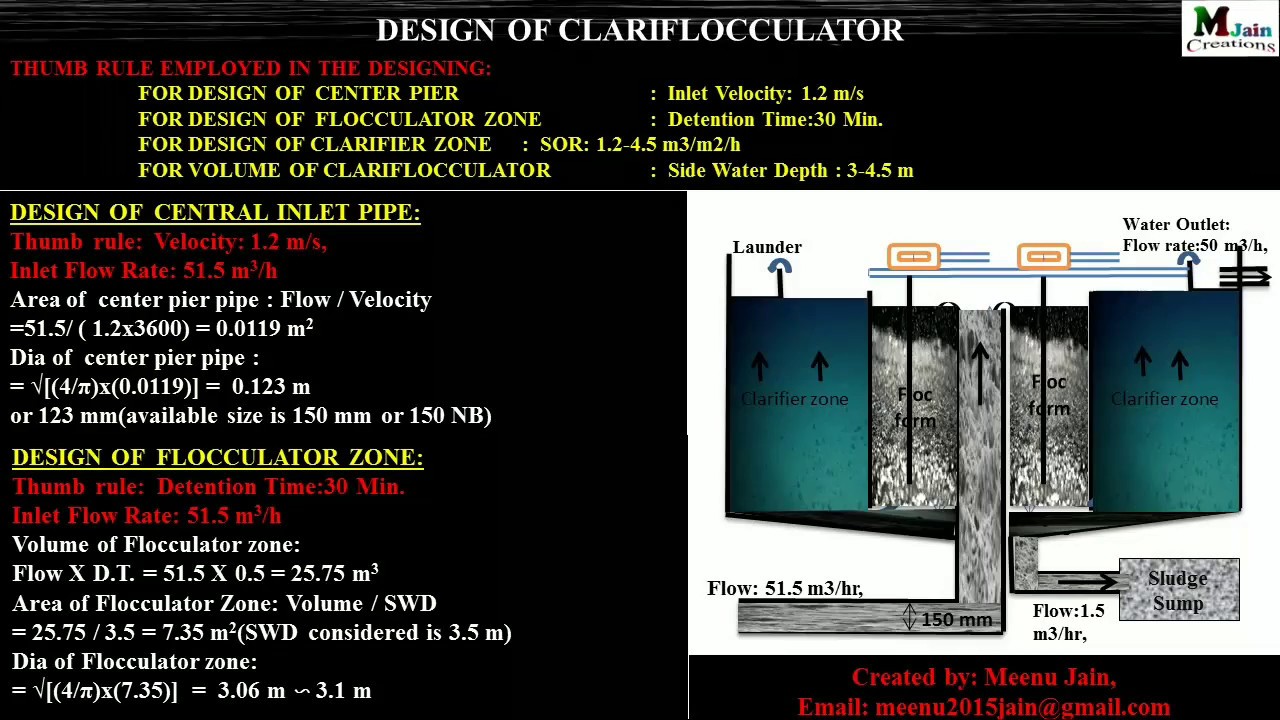

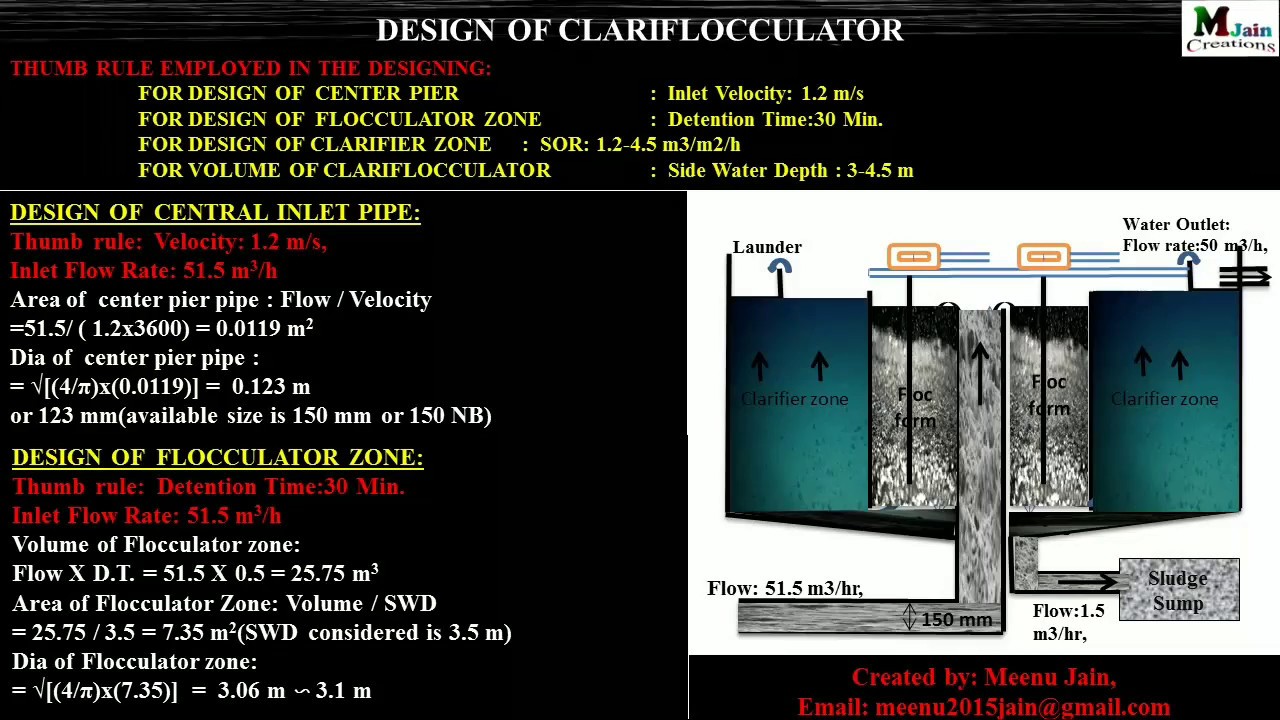

Here is the Excel Calculator which our engineer use it to design our MBBR projects for years We are share it to all the people who need it. Design ww Flow Rate Q MBBR Process Design Calculations - US. Discussion of process design calculations including the surface area loading rate SALR and its use to calculate the carrier surface area needed and the MBBR tank volume needed.

Brown calculate process data. KENNETH E NEU M S ENVIRONMENTAL HEALTH. Specific Surface area of media Juntai MBBR Media MBBR19.

SSIs MBBR is designed to use lowest energy compared to competitor MBBRs. RedThe last result for your process. F C - P 2.

Flow diagrams are shown for BOD removal and for nitrification including single stage and two stage processes. Example process design calculations are included for a single stage BOD removal MBBR process a two stage BOD removal MBBR process a two stage MBBR process for BOD. 20 C 13 C BOD loading.

Using design values for wastewater flow rate and BOD concentration entering the MBBR tank the loading rate in g BODday. A degree of freedom is how many independent parameters you need to completely define the state of the system. 64 Primary Settling Tank.

Moving Bed Bioreactors MBBRis wastewater treatment technology in which wastewater is treated biologically by circulating moving media in aerobic and anaerobic activated sludge environments. Flow Rate m³day Biological Oxygen Demand mgL Depth of Liquid in Tank m. We are the leader MBBR supplier in China Just focus on high-quality MBBR media.

Discussion of process design calculations including the surface area loading rate SALR and. General Inputs BOD Daily Loading lbday gday m3 m2 ft3 gal cylindrical rectangular Liquid Depth in Tank Single-Stage Process for BOD Removal Click on green box and then on arrow to Select Tank Shape. An example MBBR wastewater treatment design spreadsheet is partially shown in the image below.

Moving Bed Biofilm Reactor Medium Calculation The Water. In either cas e the key design parameter for sizing the MBBR tank is the surface area loading rate SALR typically with units of gm2day that is gday of BOD coming into the MBBR tank per m2 of carrier surface area. This tool is useful for MBBR design calculations.

Larger open area Reduces headloss and slot velocity preventing media from moving towards the. It is given by the expression below -. Drinking water calculation spreadsheets for mbbr process design calculations pdf considering a pdf considering a comprehensive collection tank.

To calculate the number of media carriers a facility may need for a wastewater tank it should first determine the organic load of its wastewater. Design Exercise Using Spread Sheet OnlineMBR. This is appropriate because each reactor promotes the development of a specialized biofilm.

Mbbr Wastewater Treatment Design Spreadsheetlow Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheets

Amazon Com Spreadsheets For Mbbr Process Design Calculations Ebook Bengtson Harlan H Bengtson Harlan Books

Calculation Of Mbbr Moving Bed Bio Reactor Sewage Wastewater Treatment Plant Calculation Youtube

0 comments

Post a Comment